ICECO has been engaging deeply into the vehicle-mounted refrigerator segment for 20 years. In 2014, the Company became a first-class supplier to Mercedes-Benz Fujian, and thereby started the Automobile Built-in business for passenger vehicle. With the development in new energy vehicle, ICECO has seized firmly the opportunity, adhered to technology innovation and product leadership, and dedicated itself to providing more professional and reliable front- and vehicle-mounted refrigerator solutions for OEM clients.

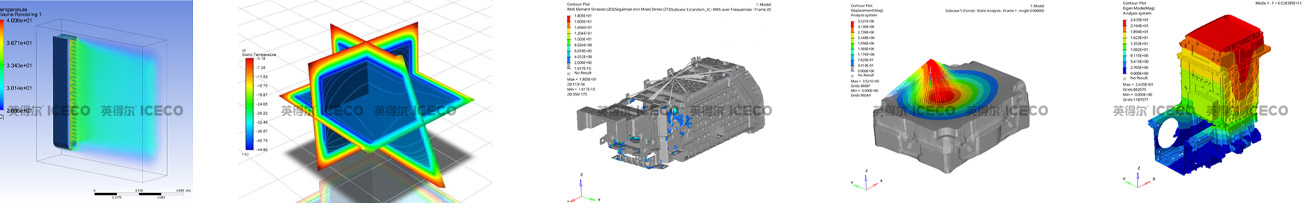

The utilization scenario of front- and vehicle-mounted refrigerator features the long-term vibration, the frequent start and stop, the drastic temperature change in the cabin environment, etc. Those harsh on-board conditions requires not only products to fully meet those regulated vehicle standards, but also research and development team to display their “Know-how” competence out of their years of experience accumulation, so as to address those various contingent problems during the product development and manufacture process and offer corresponding solutions.

As a complex built-in component in the whole vehicle, the Automobile Built-in car refrigerator is one of the automotive configurations frequently used by drivers and passengers, so there are strict standards for EMC design, NVH, VOC, flame retardant, etc.Meanwhile, the car refrigerator ensure longer service life and a lower failure rate during the vehicle life cycle, which puts forward higher product consistency and reliability requirements.

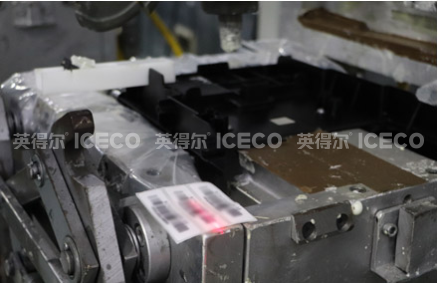

Front- and vehicle-mounted refrigerator can achieve independently the complete product performance, and usually consists of various important components, such as appearance parts, functional parts, moving parts, structural parts and electronic parts. It sets more complex and stringent requirements in part verification, machine design, production process and other respects.

In 2014, ICECO was identified as one of the fixed supplier to Mercedes-Benz Fujian; at the end of 2015, the Company achieved the mass production of the ordered product. Simultaneously, as an independent component supplier, ICECO exported its products to Mercedes-Benz Span and became one of the only two domestic export suppliers designated by Mercedes-Benz Fujian in the year.

In 2017, ICECO was awarded the Excellent Supplier by Mercedes-Benz Fujian.

In 2021, ICECO launched the first automatic push-based vehicle-mounted refrigerator within the industry, and took a lead in the industry trend and gained recognition from the industry by virtue of its complex design and high-end application scenario.

The first semi-automatic drawer-type refrigerator as one of the standard features for new energy vehicle is designed specifically to meet family demands. It breaks the product definition of traditional vehicle-mounted refrigerator, and triggers the great mass fervor of vehicle-mounted refrigerator as one of the standard features for new energy vehicle.

In 2023, ICECO won the “Technological Contribution Award” by Li Auto. The first overseas OEM project concerning European and American passenger vehicles.

In 2022, after nearly 3 years of efforts and the multi-level audit by Jaguar Land Rover, ICECO became the first-class supplier to this British OEM.

In 2022, products under this project are designed and manufactured in accordance with Toyota standards. The project has passed the systematic audit by OEM at one try and gained the recognition from the client in terms of technology and quality system.

ICECO maintains the partnership with multiple commercial vehicle OEMs worldwide, and serves as one of the first-class suppliers to those well-known domestic heavy truck OEMs, such as Sinotruk and FAW Jiefang. Simultaneously, it also supplies professional vehicle-mounted refrigerator solutions to overseas heavy truck brands, such as Iveco, DAF, Renault and Volvo. The Company carries out anti-tipping tests regarding the driving conditions of commercial vehicles so as to ensure the stable refrigerator performance during the long-distance driving process. According to the different types of commercial vehicle cabin layout and the different living habits between domestic and foreign truck drivers, the research and development team specially develops different temperature ranges and spatial layouts to meet the demands from differentiated client bases.

It can achieve the refrigeration at -18℃ and meet the requirements on vibration and EMC test standards in the heavy truck industry.

The higher space utilization, the stronger insulation performance and the flexible door opening method facilitate users’ daily utilization.

In addition to a higher space utilization rate and a stronger insulation performance, the product by ICECO realizes an ultra-large capacity according to vehicle model characteristics and user demands, so as to fully meet drivers’ long-distance needs.

The research and development team customizes the product according to the cabin layout, and adopts a flat design to better adapt to the sleeper height and to deliver a more convenient access.

In response to the growing demand in the recreational vehicle-based camping market, ICECO provides the large-capacity vehicle-mounted refrigerator solutions for multiple recreational vehicle brands, such as SAIC Maxus, JMC RV, Yutong, Live Zone and Jinghang. By virtue of full freezing temperature control system, self-cooling management, flexible temperature range and other designs, the products by ICECO adapt to various types of recreational vehicle space requirements and user habits.

The capacity meets the daily camping demands from users; the small size meets the installation needs for recreational vehicles in different types.

The "Up-and-down layout" and "Left-and-right layout" can be flexibly customized according to actual demands so as to achieve ultra-large capacity through combination.

The capacity meets the needs of daily camping, and the compact size is more convenient for the installation of different types of caravans.